On-site calibration

Calibration in your company

Our highly qualified technicians and engineers are at your service throughout Europe and calibrate your test equipment and measuring stations on site. Benefit from our technical expertise and the use of high-precision equipment. With traceability to national and international standards and norms, test equipment monitoring is also in safe hands on site. With our comprehensive range of services, we can perform both traceable ISO/factory calibrations on site, as well as accredited calibrations in accordance with DIN EN ISO/IEC 17025:2018.

More service – more safety

For anyone who uses their measuring devices on a daily basis, every day of downtime means valuable time lost. esz AG calibration & metrology will come to your location and carry out the calibration on-site. You benefit in several ways, as there are no transport times for the devices. This significantly increases the availability of your test equipment. In addition, you minimise the risk of transport damage and the administrative work involved in managing your measuring devices is significantly reduced.

Calibration in the mobile laboratory or on your premises

Our mobile calibration laboratories and calibration containers enable customised use. Our mobile calibration laboratories are optimally adapted and equipped to meet your requirements. Due to the short throughput times, calibration containers and mobile calibration laboratories are very suitable for large quantities of test equipment and where space is limited. The systems used are similar to the workstations in our permanent laboratories. In this way, we guarantee that the measuring devices will always function perfectly and provide reliable measurement results.

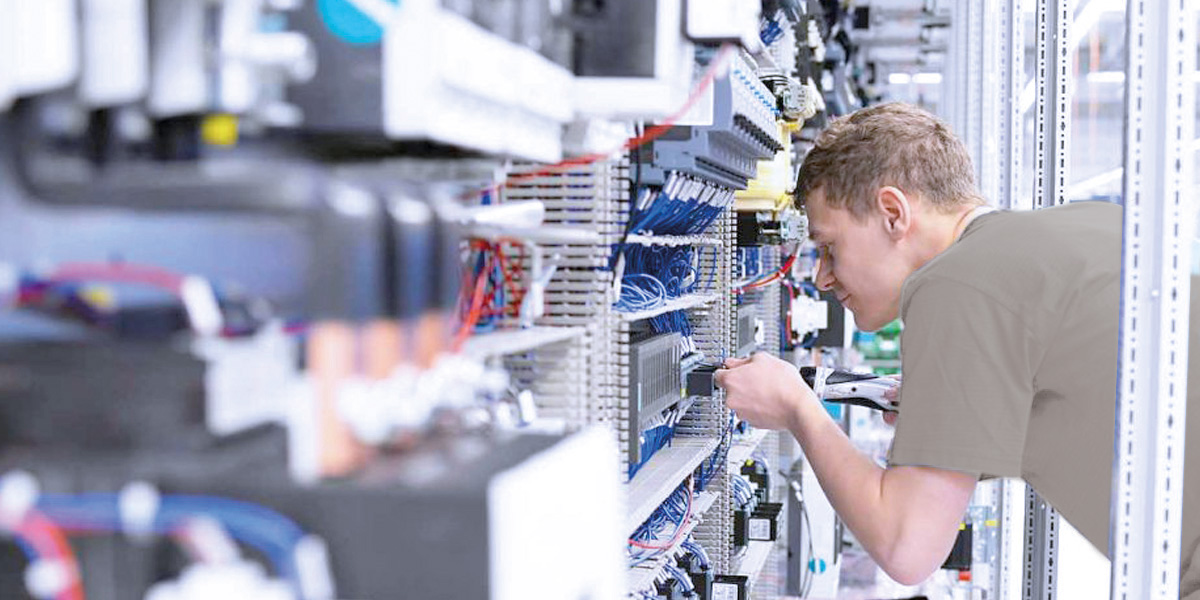

Calibration of stationary test benches and systems

To ensure that your processes and procedures are safe, you must be able to rely on the accuracy and reliability of your measuring equipment. Regular calibration is therefore important to ensure the quality of your products and systems. In addition to the direct calibration of measuring points in the process, esz AG covers a wide range of standard measurement technology on-site. We specialise in the calibration of test benches with numerous measurement parameters. These are often systems that cannot be removed or shipped.

Your on-site calibration offer

We’ll be happy to provide you with a no obligation quote for the calibration of your measuring devices.

Your benefits

- Minimise downtime for measuring devices

- Standard-compliant calibration, like in the laboratory

- No transportation costs and no transportation risk

- Calibration of large quantities

- Own laboratory containers available

- ISO/factory calibrations and accredited calibrations possible

More information

As the system is also used as a workstation in the permanent laboratory, perfect device function is always guaranteed both before and after transportation to on-site operations. In addition, simple plausibility checks are carried out before and after dismantling and reassembly in order to guarantee flawless operation at all times. Smooth processes for on-site orders are made possible by checklists and tight organisation.

First of all, we discuss the technical feasibility of on-site calibration with you in accordance with the technical conditions of the device (contact by the technical department, agreement on special calibration requirements, clarification and evaluation of the conditions, the workplace and the on-site supervisor, determination of the ambient conditions such as measuring room temperature, humidity or the local gravitational acceleration at the place of use). Once the technical implementation has been clarified, our internal sales team will coordinate the dates with you. Approval is only given after confirmation by the laboratory management, the person responsible for the technical deadline and the technician carrying out the work.

Putting together the technical equipment, instructions, accessories and connection technology, checking the plausibility of the standards and checking compliance with the measurement uncertainty is a major challenge for our technicians. You update the calibration database and form data and take care of mobile activation. The printer, laptop and thermohygrometer are checked for operational readiness and reserved for the day of use.

Smooth logistical implementation is required for successful on-site calibration. This includes defining the arrival and departure details, reserving a vehicle from the fleet pool, reserving accommodation, clarifying customs and safety regulations at the location, ensuring accessibility, tolls, fuel, precise route planning and appropriate and proper transportation of the standards to the customer. In order to maintain thermal settling times, we prepare standards and calibration items in the measuring room for at least eight hours. This is best done overnight on the day of arrival after the workplace has been set up.