Safety check

Safety check

according to DGUV V3

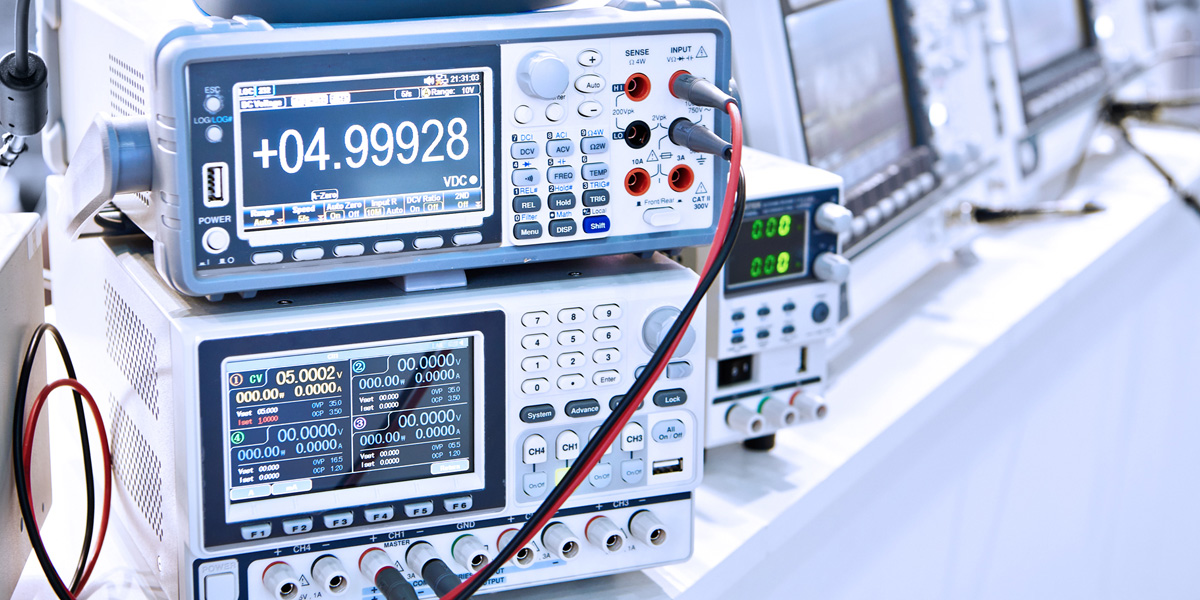

If you use electrical measuring devices in your company, you must ensure that they are regularly checked and maintained. This is the only way to ensure that your test equipment works safely and correctly. esz AG carries out the safety testing of your electrical measuring equipment in accordance with DGUV V3 as part of your calibration order or as a separate individual order. A trained specialist carries out the test steps in accordance with DGUV V3 before calibration in our laboratories. If the result is positive in accordance with DGUV V3 and VDE 0701-0702, you will receive a legally compliant test report and the device will be marked with a test sticker.

Safety testing and documentation in accordance with DGUV V3 test protocols

Safety tests of electrical devices are divided into the following three sections:

- visual inspection

- functional test

- measurement control

We test your devices comprehensively for functionality and safety in these three steps. We also determine how your measuring devices react to different scenarios, such as a short circuit. We document all inspection steps and the values determined during the inspection in our inspection software in accordance with the DGUV V3 inspection protocol.

Repair and calibration directly in-house

If your device is found to be faulty or defective during the inspection, we will inform you immediately. On request, we can repair your defective device quickly and competently. This saves you time and money. We then carry out your calibration job in our laboratories.

Request a safety check now

Submit your request for a safety check here

We have more than 40,000 manufacturer-independent operating instructions and thousands of spare parts for a wide range of devices.

Phone: +49 8141 88887-0

Your benefits

- Everything from a single source

- Safety check As part of the calibration of your electrical measuring devices

- Reduced downtime and service life of your test equipment

- Repair and adjustment directly in the connected service laboratory

- Optimal price-performance ratio

- Use of the latest measurement technology

- Lower maintenance and repair costs

- Increased safety for your employees

- Clear cost planning thanks to standardised prices

- Test protocols for added safety

More information

The testing of electrical devices, the testing of portable devices and the testing of electrical equipment is generally due every four years. However, certain factors, such as increased stress, increased wear or increased risk, may mean that testing is required more frequently.

A functional test is generally required for the testing of electrical devices, the testing of portable devices and the testing of electrical equipment. This checks whether the device meets the requirements and is working properly.

Inadequate testing of electrical devices, testing of portable devices and testing of electrical equipment can result in the device concerned no longer meeting the safety requirements and therefore posing an increased risk of accidents and damage.

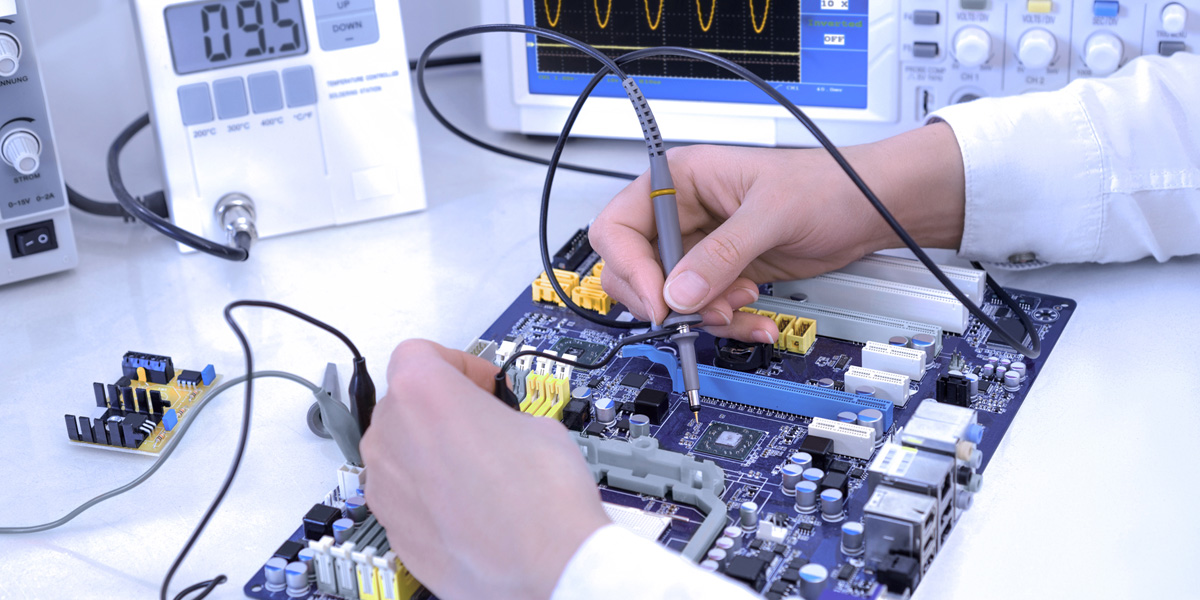

The technician begins with a visual inspection of the device. He looks for visible damage such as cracks, dents or soiling. If any damage is found, it should be repaired before proceeding with further testing procedures.

This is followed by the functional test. For this purpose, the equipment is connected to a current or voltage source and the technician tests whether the equipment complies with the required operating voltage and current range and whether it functions correctly. If necessary, measurements of the insulation resistance and the contact resistances should also be carried out. Finally, the equipment is tested for effectiveness.

The technician documents all results within our calibration expert laboratory software and then creates a test report.